GRO 2 NEW forged pattern Gravel bike wheelset 45mm depth 24mm internal width

- yuan an

- Xiamen

- 7-15days

- 1000pair

-Our materials R&D department works every day to create newer, lighter and stronger carbon fiber materials and resins. The forging pattern is also based on the original silk of the Japanese Toray T700 and T800, but it has changed the way it is woven, with our unique resin. In the case of the same weight ratio, a more brilliant luster is added. Forging patterns in natural light will reflect different visual effects. If you are already visually tired of UD, 12K, 3K, then the new forging pattern will be a good choice for you. It will definitely bring you a different kind of confidence, like putting on a prince's new clothes.

-Using more than 50% of the T800 carbon cloth

-Stiffness, weight, and stress absorption are more balanced.

-Internal width of 24mm, an outer width of 31mm, and a height of 45mm, so it can use tires of 32~50C.

-A unique and distinctive carbon fiber surface "forged pattern”

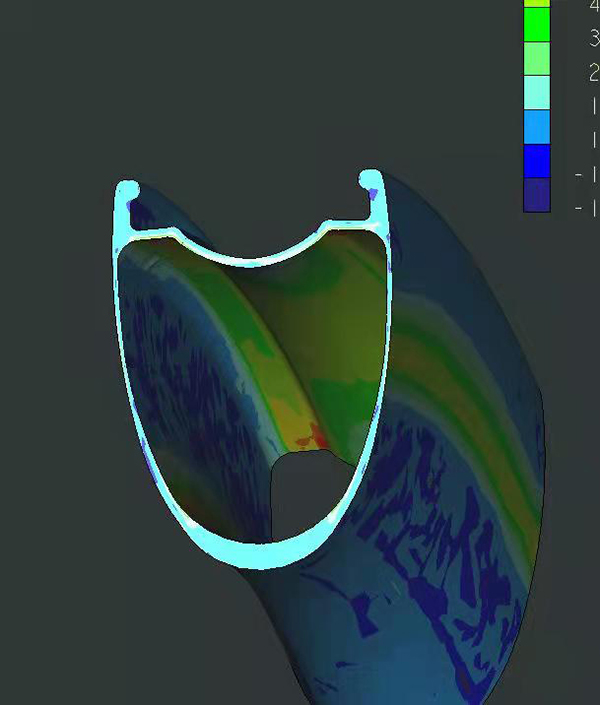

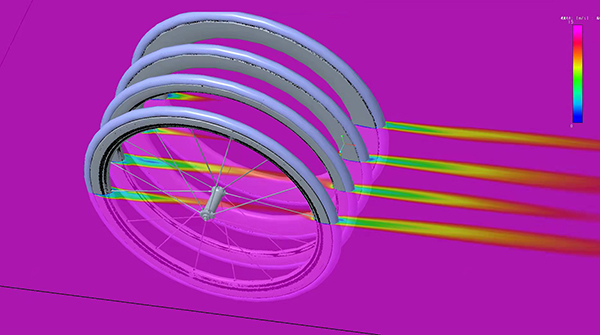

-Rim shape is U-V. The performance in aerodynamics is also extremely eye-catching

As the Gravel bike becomes more and more mature in the market, everyone feels more happiness and better riding experience brought by the Gravel bike, and there are more demands for the function of the Gravel bike, not only hoping to complete the comprehensive use of muddy roads and urban roads, but also putting forward higher requirements for it. So we have a new idea for the wheelset of the Gravel bike. Gravel GRO2 is considered in many ways. Using more than 50% of the T800 carbon cloth, the GRO2 achieves a lighter weight, and in the stress performance, the indicators reach the best value, stiffness, weight, and stress absorption are more balanced.

Gro2 has an internal width of 24mm, an outer width of 31mm, and a height of 45mm, so it can use tires of 32~50C. The rim shape is U-V. The performance in aerodynamics is also extremely eye-catching, and the test uses 35C tires to compare 35mm, 40mm, 45mm, 50mm. In tests with speeds of less than 40KM/H, GRO2 was able to stay ahead of the curve. Even more striking is GRO2's use of a special surface material for the first time, which is surprising at first sight. It is a unique and distinctive carbon fiber surface. We call it a forged pattern.

Rims:

Modle:YAG45-04

Size:700C

Use:Gravel disc brake

Type:Tubeless

Internal width:24mm

Outer width:31mm

Depth:45mm

ERD:538.5mm (not including nipple head dimension)

Rim weight:450+/-15g

Weight Limit:130kg

Spoke holes:16/18/20/21/24/28/32H

Spoke Hole Angle±7°

Spoke Tension:100 ~110kgf (radial) /115 ~130kgf (disc) front, 120~130kgf rear

Tyre Pressure:130psi recommended max

Tire:32C~50C recommended

Wheelset weight:1450g

Spokes:

Sapim cx-ray/Pillar 1423/Pillar wing 20

Color:black

Nipple:

Sapim Secure Lock

Color:black

Hub options:

HUB TYPE:Ratchet system

CASSETTE BODY:SHIMANO&XDR

FRONT HUB:12*100mm

REAR HUB:12*142mm

BRAKE INTERFACE:Center lock

ECHNOLOGY

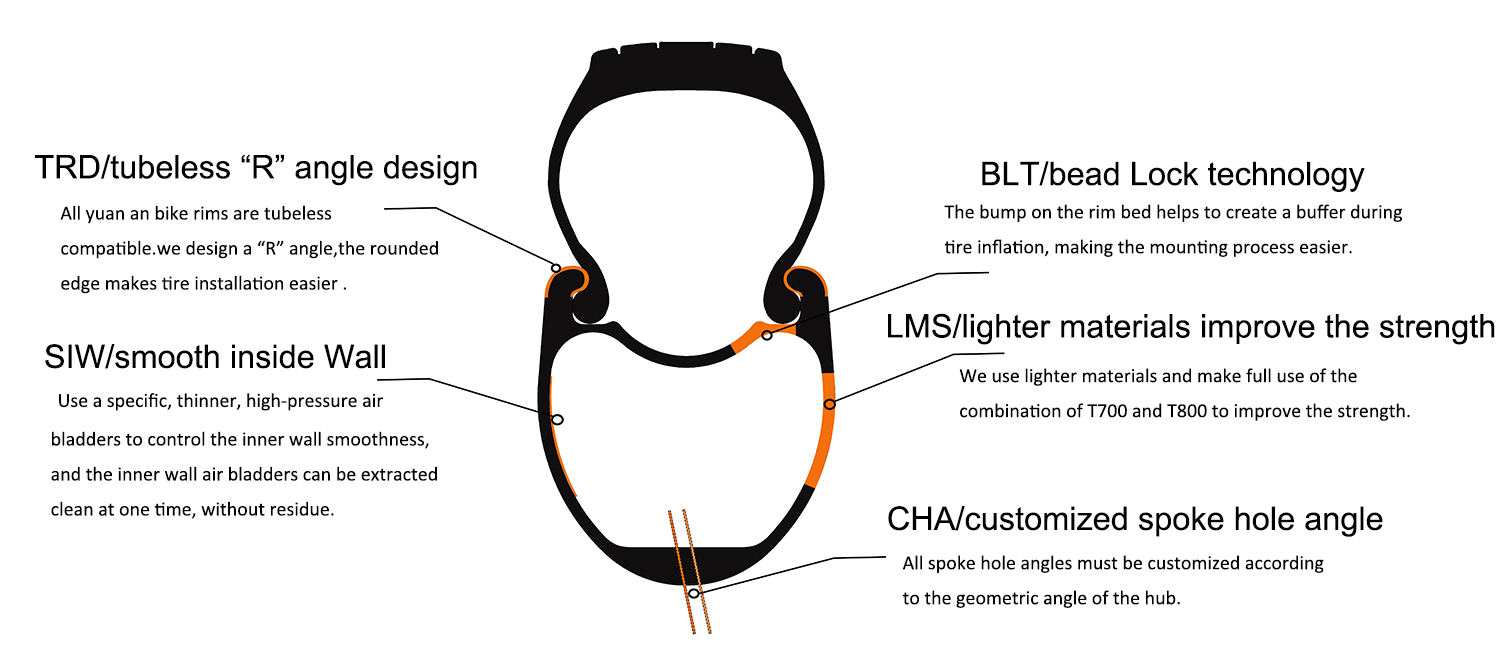

CHA/Customized spoke hole angle

All spoke hole angles must be customized according to the geometric angle of the hub.all drilled holes are inspected to ensure they are free of burrs.You can request a customized drilling pattern if you have a unique wheel build.

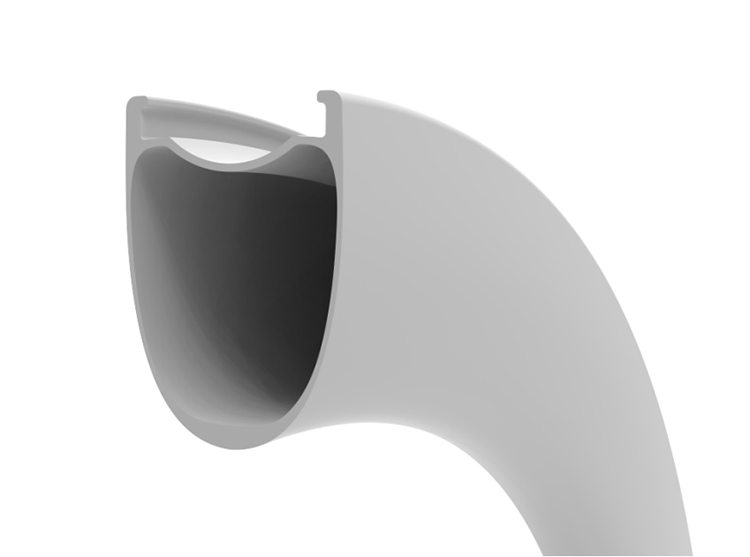

TRD/Tubeless R angle design

All yuan an bike are tubeless compatible.We design a R angle,The rounded edge makes tire installation easier and offers increased support during hard cornering with a softer edge and larger surface area.

LMS/lighter materials improve the strength

We use lighter materials and make full use of the combination of T700 and T800 to improve the strength.

SIW/smooth Inside Wall

We use a specific, thinner, high-pressure air bladders to control the inner wall smoothness, and the inner wall air bladders can be extracted clean at one time, without residue, not only effectively improve the tightness of the carbon fiber yarn, but also allow the spoke cap to be more tightly integrated with the spoke hole

OPT/one piece technology

Compared to the technology of 3 piece, our one piece tech is more technically difficult and takes longer to produce, but the rigidity of the rim is at least 7% higher

BLT/Bead Lock technology

The bump on the rim bed helps to create a buffer during tire inflation, making the mounting process easier. When the tire is mounted, the raised portion reinforces the tire bead, making it harder to “burp” or fall back into the drop channel.

URT/Unique resin technology

To improve the stability of the wheel, we think the material control is the root.So we import carbon fiber raw yarn from Toray, Japan, and mix with the high-temperature-resistant resin which researched and developed by our own, weaving them to be prepreg .So, from the source we firmly control the quality.

EPT/Environmental protection technology demoulding

Compared with many oil-based mold release agents, we use a neutral mold release agent imported from Germany, because we use labeled "NAK80 steel", which is a very high-strength abrasive tool, compared to ordinary P40 For steel, NAK80 has a firmer surface and a smoother rim surface.

HBW/Hand bulit wheel

From prototype to production, every wheel gets assembled by hand. There is no substitute for the experience and meticulous attention to detail that a human being brings to the craft of wheel building.

Check more technology